What is preventative maintenance?

- Identifying problems which may lead to unnecessary repairs and downtime.

- Recording, controlling and analysing.

- Maintaining physical conditioning.

- Ensuring maximum results are achieved the following activities need to be applied consistently;

- Comprehensive inspections including

- Body inspections, both interior and exterior

- Electrical

- Mechanical

- Tyre inspections

- Vehicles need to be cleaned on a regular basis to prevent rust, promote hygiene and improve brand image

- Comprehensive inspections including

Regular cleaning will prevent rusting, whilst applying rust treatment will prevent existing rust spreading

Regular comprehensive inspections not only record, analyse and inform fleet operators of the condition of their fleet, they identify any damages related to negligence and abuse thus allowing fleet operators the opportunity to recover costs. The long term benefits are more substantial in that a standard is maintained altering the mindset against abuse and negligence.

Early detection negates crisis management, as much as dealers and service centres would like to accommodate their customers in an emergency they too have work schedules to maintain, your vehicles urgent repairs will therefore be delayed, resulting in unexpected expenses such as vehicle hire and costs related to downtime.

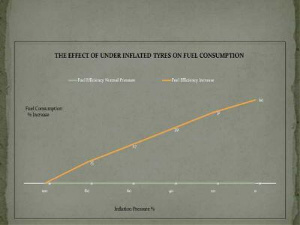

There are numerous examples in which preventative maintenance can reduce costs and prevent downtime, none more consequential than tyre maintenance. Incorrect tyre pressures affect the handling of a vehicle, increasing wear on components such as braking and steering, driving with only one under inflated tyre can increase fuel consumption by 4%, whilst greatly reducing the lifespan of the tyre. Early detection against any cuts, cracks, blisters or bulges can prevent sudden tyre failure or even blow outs.

| Under Inflation | Correct Inflation | Over Inflation |

|  |  |

| Excessive Shoulder Wear | Even Wear | Excessive Centre Wear |

Click graph to enlarge | ||

|