Why Preventative Maintenance?

Efficiency,

optimisation and cost reduction are key phrases in any business, this

service offers fleet operators a cost effective solution with the aim of

adding value and achieving these objectives.

Dependant on your

business transportation may not be considered your core function,

however if you own, manage or lease a fleet of vehicles it means

distribution forms an important link in your company’s total supply

chain, consequently impacting on the profit and loss of your business.

Commercial vehicles serve a dual purpose, conveying product and brand

marketing the effectiveness of which is largely dependent on driver

behaviour and physical condition. A fleet of vehicles will complete

thousands of kilometres per year and are constantly exposed to elements

such as adverse weather and road conditions, traffic congestion and

driver abuse. These elements are largely responsible for the accelerated

wear and tear of vehicles.

Dealers offer numerous after sales

products when purchasing a vehicle such as service and maintenance plans

in addition to factory warranties, at additional costs. Similarly

operational and maintenance options are available when leasing, these

services are designed to offer owners and the lessee added cover,

however they do not cover against negligence and abuse.

The

effective maintenance of a vehicle requires preventative action in

conjunction with scheduled maintenance. When leasing preventative

maintenance is a pre-requisite, furthermore the lessee is obliged to

conform to the ‘savrala’ fair wear and tear guide, this guideline serves

as a indicator to the required standard of a vehicle at the end of a

lease period, the lessee is therefore liable for all costs related to

repairing the vehicle to meet this standard. Maintaining the vehicle

throughout the lease period is crucial in avoiding exorbitant expenses

at the end of a lease term.

One of the largest overhead expenses

incurred as a commercial vehicle owner will be costs incurred due to

unexpected repairs as a result of negligence and abuse. To quantify the

cost reduction through preventative maintenance you need to consider

both tangible and intangible costs of corrective action such as vehicle

downtime, loss in production, loss in sales, customer perception,

service levels etc.

Studies have shown that fleet operating costs may be reduced by as much as 20% through effective preventative maintenance resulting in a 30% reduction in vehicle downtime, increased productivity and a reduction in CO2 emisions.

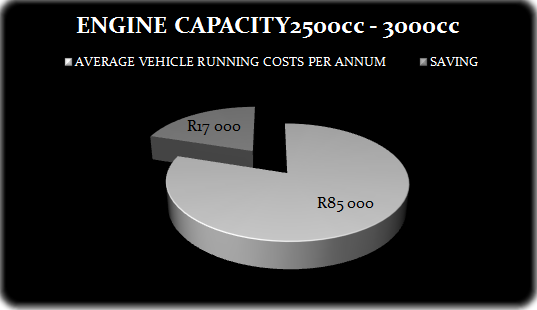

As an example the average operating costs for a vehicle with a engine capacity of between 2500cc and 300occ travelling 50000km per annum is approximately R85 000. These include relative fuel, servicing, repairs, tyres and lubrication costs, if consistent effective preventative maintenance is applied will result in a significant annual saving of approximately R17 000.